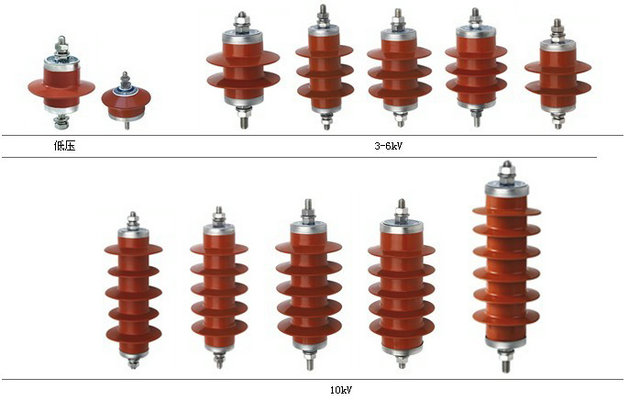

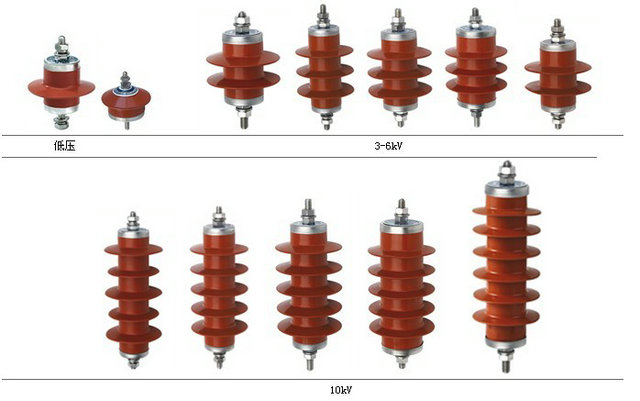

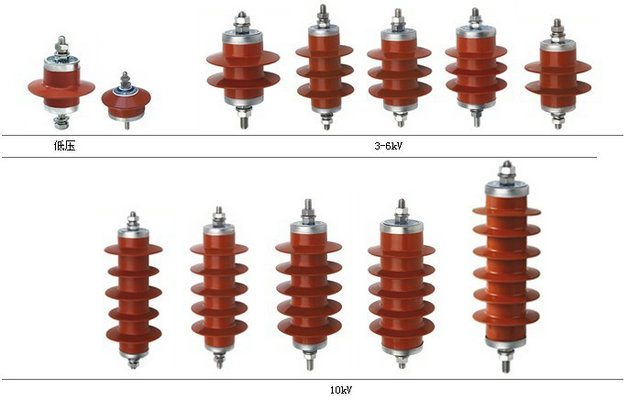

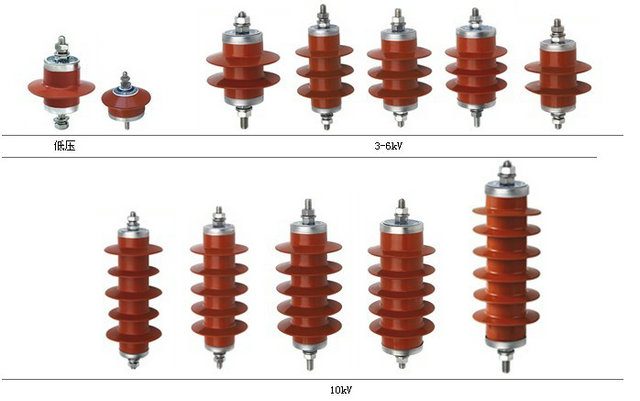

Composite sheathed metal zinc oxide arrester

Composite sheathed metal zinc oxide arrester

The core working element of the product is made of multi-element metal oxide powder mainly composed of zinc oxide, which has excellent nonlinear volt ampere characteristics, fast steep wave response and large flow capacity. Products with gap adopt self blowing gap and pressure equalizing radiation structure, which reduces the dispersion of discharge and has small impact coefficient.

Composite sheathed metal zinc oxide arrester

The core working element of the product is made of multi-element metal oxide powder mainly composed of zinc oxide, which has excellent nonlinear volt ampere characteristics, fast steep wave response and large flow capacity. Products with gap adopt self blowing gap and pressure equalizing radiation structure, which reduces the dispersion of discharge and has small impact coefficient.

The adoption of composite insulating jacket conforms to the development trend of miniaturization, security and maintenance free of international electric power products. Compared with traditional inorganic materials such as ceramics and glass, polymer organic composites have the advantages of small size, light weight, pollution resistance, cleaning free, explosion-proof and vibration proof. It is a lightning protection component of integrated and modularized medium and high voltage power transmission and transformation equipment.

Purpose and executive standard:

This product is used in power generation, transmission, transformation and distribution systems of AC 220kV and below, and is used to limit the amplitude of lightning and overvoltage during internal operation of the system to the specified level. It is the basic equipment for insulation coordination of the entire system. At the same time, this product cannot be used to limit resonance overvoltage, and other methods are required for system harmonic elimination.

The model of this product is prepared in accordance with JB/T8459-1996 Preparation Method of Arrester Product Model, and the gapless product complies with GB11032-2000 AC Gapless Metal Oxide Arrester; Products with gaps shall comply with JB/T9672-2005 Metal Oxide Arresters with Series Gaps. Important parameters and configuration methods not clearly defined in the above standards shall be corrected according to the requirements of DL/T620-1997 Overvoltage Protection and Insulation Coordination for AC Electrical Installations.

Service conditions:

The normal use conditions of conventional products are as follows:

*Ambient temperature: no higher than+40 ℃, no lower than - 40 ℃;

*Altitude: no more than 2000m;

*Power frequency: 50 ± 2Hz; 60±2Hz;

*Seismic intensity: below 7 degrees;

*Wind speed: 35m/s;

*Cleaning free conditions: areas with medium pollution and below;

*For gapless products, the power frequency voltage applied for a long time shall not exceed the continuous operation voltage of the arrester;

For products with gaps, the short-time power frequency voltage rise at the installation point shall not exceed the rated voltage of the arrester.

The arrester shall be specially made when it is used for a long time under the following abnormal conditions, and shall be specified when ordering:

*Temperature or altitude exceeding the standard (plateau, tropical zone, cold zone, fully enclosed cabinet, close to electric furnace, etc.)

*The use environment has serious moisture or corrosive gas impurities (water, salt field, chemical plant, etc.);

*Strong ultraviolet radiation (plateau, drought area with strong sunshine, etc.);

*Extremely polluted areas (mine working face, construction site working face, etc.).

Model definition:

The definition of this product model is in accordance with JB/T8459-1996 Preparation Method of Arrester Product Models. The specific model description is as follows: